The Many Benefits of Direct Drying with CAPSTONE Microturbines

As drying is an essential process across many industries, it is important to find a solution that is both efficient and cost-effective. An innovative technology that fits perfectly to this task is the use of CAPSTONE cogeneration microturbines. When generating electricity, the microturbine produces electricity, together with extremely clean flue gas that can be fully utilized in the drying process. A custom installation from IVITAS GREEN POWER with this design can reach an extremely impressive efficiency of 96 - 98%.

Clean flue gas takes center stage

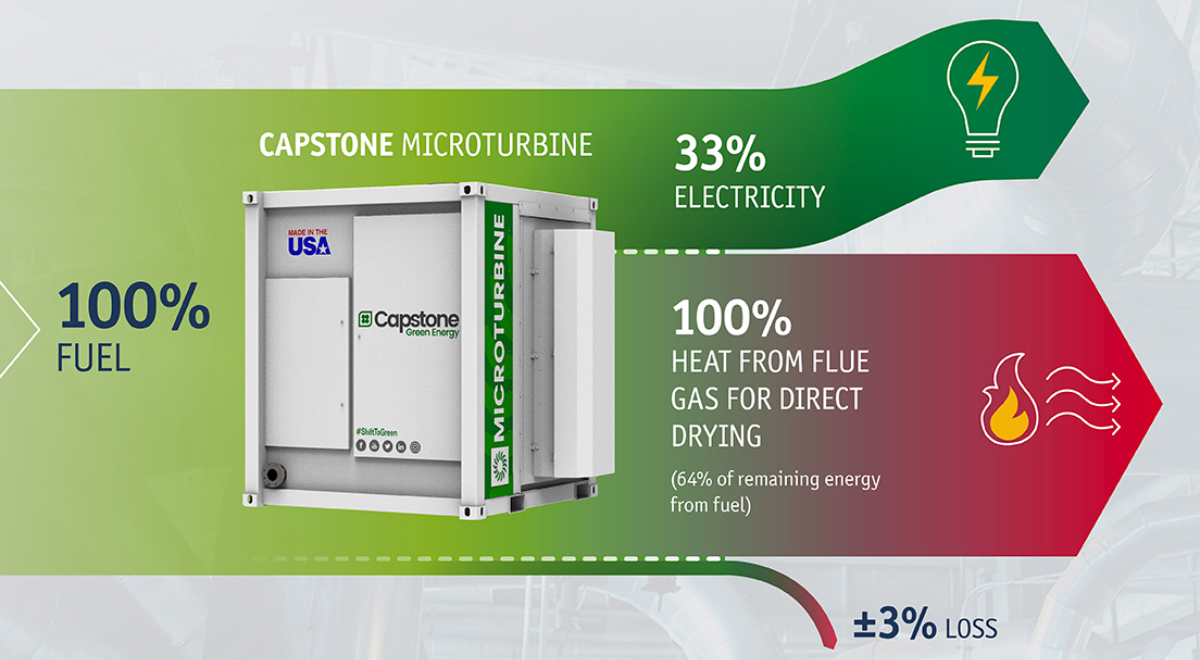

So, how does it all work? Well, this type of system converts 33% of the energy into electricity, while the remainder, in the form of flue gas, is fed into a technological solution allows for direct use of the heated gas in the drying process.

Extremely clean flue gas, with a high oxygen content of 17-19%, exits the microturbine at around 300° C. The temperature of the gas can then be adjusted to meet the specific requirements of specific drying processes. This feature is particularly interesting for direct drying, as the flue gas is completely free of oil and trace particles, avoiding any negative effects on the material that is being dried.

A wide range of temperatures for a wide range of direct drying applications

Due to their extremely clean flue gas, microturbines represent a revolutionary solution that provides many advantages for a range of industries that require drying, such as the production of building materials and paper, food processing, powder coating and agriculture, as well as the drying of sludge. Direct drying with CAPSTONE microturbines can be used for many types of drying processes, as the temperature of the flue gas can be adjusted to provide the optimum temperature.

High Efficiency + Ease of Installation = Quick ROI

The financial return on applications that use CAPSTONE microturbines as part of a complete solution from IVITAS GREEN POWER is very promising, with an ROI of 2 - 5 years. This quick payback is due to the excellent energy efficiency of the system and its relatively simple installation for drying. The CAPSTONE system does not use any lubricants or refrigerants, thus eliminating oil management duties and significantly reducing other maintenance requirements. Its high efficiency contributes to an overall reduction in drying costs.

Helping to power your sustainable future

The use of CAPSTONE microturbines for direct drying is a refreshingly innovative and efficient technology that meets the requirements of various industries. With its attractive combination of high energy efficiency and the output of clean flue gas, a customized CAPSTONE-powered direct drying system from IVITAS GREEN POWER provides you with an attractive return on your investment and contributes to the sustainability of your industrial drying processes.